Uses of Nuclear Radiation - Industrial Applications

Tracers in Industry

Tracers in Industry

Leaks from a pipeline

can be traced by adding a radioactive isotope into what ever it is carrying.

The source must have a short half-life (a few hours) so that it can

be detected as it passes through but not stay radioactive long enough

to pose a health hazard.

Leaks from a pipeline

can be traced by adding a radioactive isotope into what ever it is carrying.

The source must have a short half-life (a few hours) so that it can

be detected as it passes through but not stay radioactive long enough

to pose a health hazard.

Wear of moving

parts can be tested by making the part radioactive and monitoring the

proportion of worn parts in the lubricating oil by looking for the level

of radioactivity in it. See this page.

Wear of moving

parts can be tested by making the part radioactive and monitoring the

proportion of worn parts in the lubricating oil by looking for the level

of radioactivity in it. See this page.

A gamma source

can be used to check welds in metal parts. It is used in a similar way

to X-rays on a human body. A photographic plate is placed behind the

weld. It is exposed more where the weld is weak.

A gamma source

can be used to check welds in metal parts. It is used in a similar way

to X-rays on a human body. A photographic plate is placed behind the

weld. It is exposed more where the weld is weak.

Sterilisation of Food and Surgical Instruments

Sterilisation of Food and Surgical Instruments

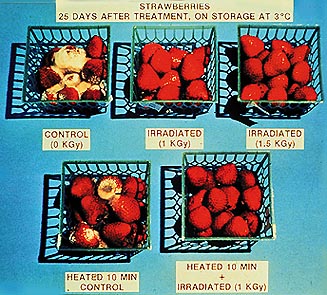

Gamma rays kill bacteria.

Gamma rays kill bacteria.

Therefore irradiating foodstuffs or surgical instruments is a good way of ensuring they are sterile. The gamma rays penetrate packaging, so the food or instrument can be sealed first and then sterilised so that re-contamination cannot occur.

Therefore irradiating foodstuffs or surgical instruments is a good way of ensuring they are sterile. The gamma rays penetrate packaging, so the food or instrument can be sealed first and then sterilised so that re-contamination cannot occur.

No radioactive source particles are allowed to get in touch with the irradiated substance.

No radioactive source particles are allowed to get in touch with the irradiated substance.

The source is sealed so that only gamma rays get out. Therefore the irradiated substance is sterile but NOT radioactive.

The source is sealed so that only gamma rays get out. Therefore the irradiated substance is sterile but NOT radioactive.

Thickness Control in Manufacturing

Thickness Control in Manufacturing

Automatic control over the thickness of paper in paper mills can be obtained by passing beta radiation through the paper and monitoring the count rate.

Automatic control over the thickness of paper in paper mills can be obtained by passing beta radiation through the paper and monitoring the count rate.

An isotope with a long half-life is used so that the count-rate hardly changes with time.

An isotope with a long half-life is used so that the count-rate hardly changes with time.

Electrical circuitry is then set up to ensure that a constant rate is maintained.

Electrical circuitry is then set up to ensure that a constant rate is maintained.

If the rate is too low the rollers automatically move closer to each other (making the paper thinner) and vice versa.

If the rate is too low the rollers automatically move closer to each other (making the paper thinner) and vice versa.