|

Just as there is electromagnetic radiation with frequencies we cannot detect with our eyes so there are "sound" waves with frequencies we cannot detect with our ears. Those with frequencies lower than those a human ear can detect are called infra-sound and those with frequencies above those we can hear are called ultrasound. (Just like we have infrared and ultraviolet for the e.m.spectrum).

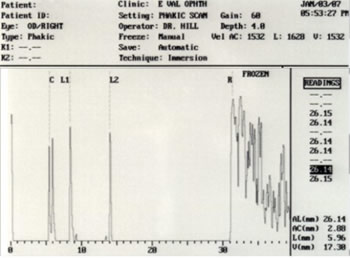

How they are produced is not covered at GCSE (you study that at A level in the Medical Physics option). All you need to know is that an electronic system can be used to produce and detect ultrasound pulses and a computer analyses the data received.An ultrasound probe both transmits pulses and receives the echoes. These are partially reflected when they meet a boundary between two media of different density. By timing how long it takes for the reflected pulse to get back to the detector we can work out how far away such a

boundary is. We do this by echo calculations.

We know the speed of sound through the medium and can read off the A Scan the time between sending the pulse and receiving the echo.

The beam of ultrasound can be focused to improve the pictur>e. The higher the frequency, the better the resolution (how much detail c>an be picked up).

The ultrasound equipment consists of:

a transducer (probe), which converts electrical signals into ultrasound, and detects the reflected signals that come back. a transducer (probe), which converts electrical signals into ultrasound, and detects the reflected signals that come back.

a signal generator that makes pulses, typically at a frequency of about 2 MHz (our upper hearing limit is 20 kHz). a signal generator that makes pulses, typically at a frequency of about 2 MHz (our upper hearing limit is 20 kHz).

a computer to convert the pattern of signals into a meaningful picture (B Scan) or displacement (intensity of pulse) against time graph (A Scan). a computer to convert the pattern of signals into a meaningful picture (B Scan) or displacement (intensity of pulse) against time graph (A Scan).

Uses of Ultrasound

Ultrasonic devices are useful because they are non-invasive (you don't have to cut into what you are looking at) and non-ionising (so you don't have to worry about increasing the probability of getting cancer!).

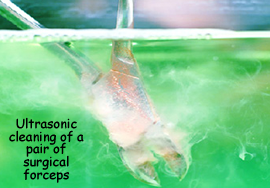

Ultrasound waves can be used in industry for cleaning. The sound pulses are sent through a fluid and the tiny bubbles formed within the vibrating fluid dislodges dirt and dust particles

Within the water (or other solvents) very small bubbles are formed - as they collapse the fluid rushes in to the gap - this is called cavitation. These bubbles are very effective at removing dirt from components as they move at very high speeds, propelled by the ultrasound waves and implode on surfaces capturing the tiny dirt particles and carrying them away in the fluid. Cleaning by using ultrasound results in a very high standard of cleanliness. Ultrasound waves can be used in industry for cleaning. The sound pulses are sent through a fluid and the tiny bubbles formed within the vibrating fluid dislodges dirt and dust particles

Within the water (or other solvents) very small bubbles are formed - as they collapse the fluid rushes in to the gap - this is called cavitation. These bubbles are very effective at removing dirt from components as they move at very high speeds, propelled by the ultrasound waves and implode on surfaces capturing the tiny dirt particles and carrying them away in the fluid. Cleaning by using ultrasound results in a very high standard of cleanliness.

|

Ultrasound waves can be used in industry for quality control. A common use for ultrasound is to check for flaws in castings. Flaws are bubbles of gas that can occur when metal is cast. As the metal solidifies, the bubbles get trapped. They can seriously weaken the casting. If they are bad enough, the casting may have to be scrapped. The ultrasound pulses reflect off the sharp changes in density between the air and metal and show up the flaw's position. Ultrasound waves can be used in industry for quality control. A common use for ultrasound is to check for flaws in castings. Flaws are bubbles of gas that can occur when metal is cast. As the metal solidifies, the bubbles get trapped. They can seriously weaken the casting. If they are bad enough, the casting may have to be scrapped. The ultrasound pulses reflect off the sharp changes in density between the air and metal and show up the flaw's position.

|

Ultrasound waves can be used in medicine for pre-natal scanning and looking at  internal organs like the heart, liver, kidneys and gall bladder. Ultrasound can also be used for treatment. Ultrasound pulses can be used to break up gallstones. In dentistry, ultrasonic pulses can clean plaque off your teeth. internal organs like the heart, liver, kidneys and gall bladder. Ultrasound can also be used for treatment. Ultrasound pulses can be used to break up gallstones. In dentistry, ultrasonic pulses can clean plaque off your teeth.

A gel is used between the probe and the body in order to get the ultrasound into the body. The gel makes good contact with the probe head and excludes all air between the body and the probe. If it was not used the big density difference between the body and the air would mean most of the ultrasound would be reflected and would never get into the body.

There are two types of scans you should know about:

The A-Scan (Amplitude of a trace varies - looks like a graph - can be used to make measurements of the size and depth of organs) The A-Scan (Amplitude of a trace varies - looks like a graph - can be used to make measurements of the size and depth of organs)

The B-Scan (Brightness of the image varies - gives a 2-d image of the slice through the body) The B-Scan (Brightness of the image varies - gives a 2-d image of the slice through the body)

|

|